Natural Gas Treatment and Fuel Gas Conditioning: Membrane Technology Applied to New Gas Finds

Poor quality natural gas/shale gas streams brought into spec for pipeline or fuel gas use, simply and economically, thanks to Membrane Technology and Research, Inc.

R&D Opportunity

All natural gas requires treatment to remove heavy hydrocarbons, known as natural gas liquids (NGLs), to meet pipeline or fuel gas specifications. Membrane modules are needed to selectively recover the heavy hydrocarbons, which can be sold to generate additional revenue.

Solution

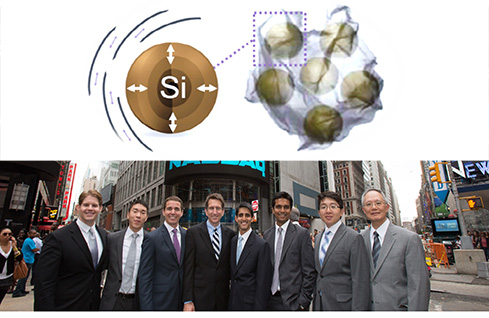

Membrane modules to separate NGLs were developed by Membrane Technology and Research, Inc. (MTR) in a Department of Energy (DOE) Phase I project. In Phase II, the company scaled up the technology, and constructed and tested a field demonstration system. MTR worked with Chevron Corporation and DOE to establish a field site for the MTR demonstration work at Chevron’s Lost Hills, CA, associated gas compression plant; the demonstration successfully brought the technology to the early commercialization stage. The modules removed NGLs to control the gas dew point, which is a critical specification used to measure gas quality and its suitability for transport in pipelines or fuel use. A few years after the field demonstration, MTR developed additional separations modules for removing impurities such as carbon dioxide, nitrogen, and/or hydrogen disulfide from a broad range of natural gas and fuel gas streams. The result was a new FuelSep™ line of business for natural gas separation technologies.

Impact

For natural gas producers that need to adjust the NGL content of the gas, the membrane process provides an attractive alternative to cryogenic/refrigeration techniques. Recovery of the NGLs results in additional sales revenues, leading to attractive payback times for operators that install MTR FuelSep processes.

The MTR Natural Gas Group has shown significant progress over the years, as new membranes and applications have been successfully installed and operated in the field. There are nearly 100 such systems installed treating streams ranging from ~1 million standard cubic feet per day (MMscfd), all the way up to 100 MMscfd. The payback times on these systems vary depending on the content of gas, among other factors, but are typically 6-12 months. Because of this, the MTR team handling these applications has grown significantly and is seeing increased revenues, especially for applications in the shale oil and shale gas production areas.

Contact

K. Lokhandwala, VP of MTR Commercial Operations kaaeid.lokhandwala@mtrinc.com

S. Joshi, Business Development Manager, MTR Natural Gas Group

sachin.joshi@mtrinc.com

H. Hussain, Process Sales Manager, MTR Natural Gas Group hesham.hussain@mtrinc.com

Related Links

Membrane Technology and Research, Inc. (MTR)

Highlight Categories

Program: NETL