A Dentist’s Journey to Save Your Teeth: From Brazil to Biotech Breakthrough

DOE user program helps even non-scientists develop and study new materials.

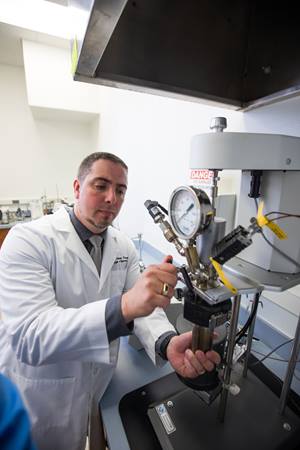

While teaching in Oklahoma, a Brazilian dentist began pursuing his idea for a new technology that would ultimately lead him to eastern Tennessee. There he had access to the discovery science expertise and world-class research facilities at Oak Ridge National Laboratory (ORNL). He used these resources to develop and test his breakthrough: the world’s first long-acting antibacterial adhesive resin for dental restorations.

The dentist, Fernando Luis Esteban Florez, a tenured associate professor and researcher at the University of Oklahoma College of Dentistry, is working to prevent the secondary tooth decay that bacteria cause around the edges of dental restorations, such as fillings and crowns. These secondary cavities are why most restorations need to be replaced on average every five to seven years.

“My idea was to develop dental adhesives that would provide long-term protection from oral bacteria,” said Esteban Florez, the lead inventor. “In the U.S. alone, a long-acting antibacterial dental adhesive could help prevent more than 60 million dental procedures per year and save patients over $5 billion annually.

“But as a dentist with limited training in scientific research, developing and testing my idea for antibacterial nanoparticles and putting them in a clinical product seemed out of reach.”

Esteban Florez and Sharukh Khajotia, the college’s associate dean for research and innovation and a co-inventor, learned about the Office of Science user facilities operated by the Department of Energy (DOE) operates. These 28 user facilities, located at national laboratories nationwide, provide state-of-the-art research facilities to the global science community at little or no cost to users.

“I’m grateful for the DOE’s user program, which enabled me, a dentist without advanced scientific training, to access the world-leading expertise and resources at Oak Ridge National Laboratory. It saved me six to eight years of development time.”

Esteban Florez and Khajotia submitted a user proposal to ORNL to work with scientists at the Center for Nanophase Materials Sciences (CNMS) and the High Flux Isotope Reactor (HFIR), both of which are DOE user facilities.

With the help of the world-class researchers at these nanomaterials and neutron science facilities, the co-inventors created multifunctional nanoparticles with long-lasting antimicrobial properties that can be added to resins and other polymers used in medicine, dentistry, public health, and engineering.

The team modified titanium dioxide nanoparticles that produce highly reactive chemicals, known as reactive oxygen species, that can kill bacteria, viruses and other microorganisms. Unlike with antibiotics, microbes cannot develop resistance to these chemicals.

The nanoparticles were then dispersed in an adhesive resin commonly used by dentists. Researchers examined samples of the experimental adhesive resin using a helium-ion microscope at CNMS and small-angle neutron scattering using the Bio-SANS instrument at HFIR to determine the optimal particle shape, modifications, and dispersion method.

“The benefit of using Bio-SANS is that it allowed us to see how the proteins bonded to the nanoparticles and how well the particles dispersed within the polymer resin,” said Khajotia.

According to Esteban Florez, the experimental results showed that for the first time in dentistry, nanoparticles had dispersed without clustering and functioned well within a polymer and displayed strong antibacterial properties without light irradiation.

“We are currently talking with a leading dental products company about commercializing this patented technology for a wide range of products,” said Esteban Florez. “This extremely versatile antibacterial and antimicrobial polymer technology can work in countless applications, including dental restorations, teeth whitening products, medical devices and equipment, and in paint on surfaces throughout public places, such as at hospitals and airports, to reduce levels of bacteria and viruses.

This article was created in partnership with Oak Ridge National Laboratory, learn more about their work.

Read more stories in the Basic2Breakthrough series.