Fungi Aid Biofuel Production

Trichoderma reesei, a fungus found in soils throughout the world, produces a cellulose-degrading enzyme to break down plant material in order to obtain nutrients.

"Unlike animals that produce enzymes in the gut to breakdown food, fungi secrete enzymes into their environment to break down the surrounding carbon and nitrogen so it can absorb the nutrients as food" said the study's lead author Scott Baker.

The fungus frustrated army officials in the South Pacific theatre during World War II, because enzymes accelerated the disintegration of the cotton fabric in the fatigues and tents.

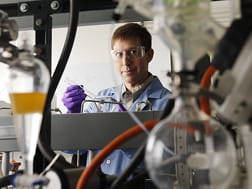

Photo Credit: Pacific Northwest National Laboratory

PNNL scientist Scott Baker is working with the DOE's Joint Genome Institute to understand how T. reesei fungus can break down biomass for better biofuel production.

In the new environment of biofuel production, scientists have hoisted T. reesei onto the shoulders of the scientific community as a new opportunity to efficiently produce biofuels.

The cellulose-degrading enzymes, called cellulases, belong to a family of enzymes called glucoside hydrolases. In essence, the enzyme takes a complex sugar, like the cellulose that makes up a significant percentage of plant biomass, and breaks it into simple sugars that can be used to make biofuels.

Using a reference strain from the Army Quartermaster, scientists bombarded T. reesei with chemical and radiological compounds to accelerate mutations. The scientists screened the mutants for a strain of T. reesei that produced and secreted more enzymes, which are being used in the industrial production of plant derived ethanol.

In 2008, scientists funded in part by the U.S. Department of Energy (DOE) Office of Science at the DOE Joint Genome Institute (JGI) mapped the genome of this important organism using the Army reference strain.

According to Eddy Rubin, DOE JGI Director in 2008 interview, "the genome of T. reesei provides us with a roadmap for accelerating research to optimize fungal strains for reducing the current prohibitively high cost of converting lignocellulose [plant biomass] to fermentable sugars [precursor of biofuels]."

Before the development of the genome sequence T. reesei mutant and reference strains, scientists did not know how they had tweaked the mutant strains to increase enzyme production.

Today, an international team consisting of researchers from the United States, Austria, and France and co-led by scientists at the DOE JGI and Pacific Northwest National Laboratory determined the nature of these mutations on the T. reesei genome.

The scientific team discovered over 200 mutations on the T. reesei genome across 60 genes.

"This study takes the science away from a random approach, which can lead to an increase in enzyme production, but, in the process, make the fungus sick. Using the reference and mutant sequences as a guide, scientists have a platform from which they can eventually determine what genes to manipulate to produce a cleaner and, ultimately, healthier strain" said Baker.

This work illuminates how this organism produces the cellulose-degrading enzyme and how scientists can bolster enzyme production further for industrial applications.

According to Baker, "this genomic study is basic science that provides the blueprint on which future applied work will rest. In order to take an organism and make it benefit society, it is crucial to understand how it works in the first place."

This work may lead to a more efficient and — more importantly —economical production of biofuels.

The mutant derivatives of the reference wild-type strain of T. reesei are currently being used to produce cellulose-degrading enzymes for industrial applications. This project provides a fertile foundation to understand how to make an industrial-strength fungus that will meet the main needs of industrial-scale biofuel production.

"To anthropomorphize this process, we want a mutant that has the mentality — don't grow, just generate more nutrients. In other words, the fungus should focus the nutrients that it absorbs toward digestive enzyme production rather than growth" said Baker.

Bioinnovation companies, like Novozymes, one of the largest producers of industrial enzymes, are working toward the goal of increasing enzyme production to make ethanol an economical alternative.

"Governments have traditionally invested a lot in the pharmaceutical industry and with good reason. However, they tend to overlook other areas of biotechnology." said Per Falholt, executive vice president and CSO of Novozymes.

Photo Credit: Sue A. Karagiosis

Trichoderma reesei strain QM6A.

Industrial biotechnology can help lead to the economical development of ethanol, which may mitigate climate change, create jobs, and boost the green economy.

This project was funded through the Office of Science as well as the Office of Energy Efficiency and Renewable Energy at the Department of Energy (DOE). DOE invests in science and solving critical issues impacting people's daily lives and the nation's future. To learn more about DOE, visit www.energy.gov.

The DOE Joint Genome Institute, supported by the Office of Science, is headquartered in Walnut Creek, Calif., and provides integrated high-throughput sequencing and computational analysis that enable systems-based scientific approaches to these challenges. To learn more about JGI, visit www.jgi.doe.gov.

Pacific Northwest National Laboratory is a Department of Energy Office of Science national laboratory where interdisciplinary teams advance science and technology and deliver solutions to America's most intractable problems in energy, national security and the environment. To learn more about PNNL, visit www.pnl.gov.

This article was written by Stacy W. Kish.